Sterilization Equipment

Autoclave (Single Drum)

- Specifications

- Key Features

Overall Size: Varies based on specific model capacity

- Heavy Duty Construction: Made with high-quality stainless steel 304 grade for durability and long-term use.

- Pressure Gauge and Release Valve: Allows easy monitoring of pressure and safe release, ensuring effective sterilization.

- 1 kW Heating Coil: Provides efficient and consistent heating for thorough sterilization.

- Silicon Gaskets: Long-lasting gaskets that ensure a secure and leak-proof seal during the sterilization process.

- Capacity: Suitable for sterilizing medical instruments, equipment, and other items in clinics, hospitals, and laboratories.

Autoclave (Double, 2.5 Drums)

- Specifications

- Key Features

Overall Size: 300 mm Diameter x 750 mm Height

- Heavy Duty Construction: Made from durable stainless steel 304 grade for strength and reliability.

- Pressure Gauge and Release Valve: Ensures safe operation and accurate pressure monitoring during the sterilization cycle.

- 2 kW Heating Coil: Provides fast and efficient heating to maintain the desired temperature for sterilization.

- Long-Lasting Silicon Gaskets: Ensures a tight, leak-proof seal, prolonging the lifespan of the unit.

- 2.5 Drum Capacity: Ideal for sterilizing larger quantities of equipment or instruments, perfect for medical and laboratory use.

Autoclave (Double Drum, Double Chamber)

- Key Features

- Microcontroller-Based (Automatic): Provides precise control over the sterilization process with automated operations for convenience and accuracy.

- Complete Stainless Steel Body: Ensures durability, corrosion resistance, and easy maintenance.

- Double-Walled Stainless Steel Construction: Enhances the unit’s structural integrity and heat retention, ensuring efficient sterilization.

- Replaceable Heater & Gasket: For easy maintenance and long-term use.

- Dial Gauge for Pressure Monitoring: Allows precise pressure monitoring during the sterilization cycle.

- Water Level Indicator: Ensures the correct water level for proper sterilization, preventing potential issues.

- Pressure Release Valve (Top and Bottom): Provides safe operation by releasing excess pressure when necessary.

- Water Inlet and Outlet Valve: For efficient water management during the sterilization process.

- Digital Indication of Temperature and Timer: Facilitates easy monitoring of sterilization parameters, ensuring accurate results.

- Available Models: Semi-Automatic and Manual options are available, catering to different operational needs.

Ethylene Oxide / ETO Sterilizer

- Specifications

- Model: Cartridge Type

- Automation: PLC-based with a 4.3-inch HMI (Human-Machine Interface) and Thermal Printer for recording sterilization parameters.

- Cycle Time: Total cycle time, including aeration mode, is only 6 hours, ensuring efficient sterilization with reduced turnaround time.

- Chamber Construction:

- Material: Stainless Steel 304 grade for high durability and corrosion resistance.

- Chamber Thickness: 3 mm for optimal structural strength.

- Outer Body: Available in either powder-coated MS (Mild Steel) or Stainless Steel, depending on customer preference.

- Door: Stainless Steel 304 grade for longevity and safety.

- Operating Gas Pressure: 1 kg/cm² for precise control of sterilization.

- Hydraulic Pressure Test: 2 kg for verifying system strength and integrity.

- Manual Operating System: In case of auto system failure, manual operation is available to ensure continued functionality.

- Electric Solenoid Valve: For precise control and perfect automation of the sterilization cycle.

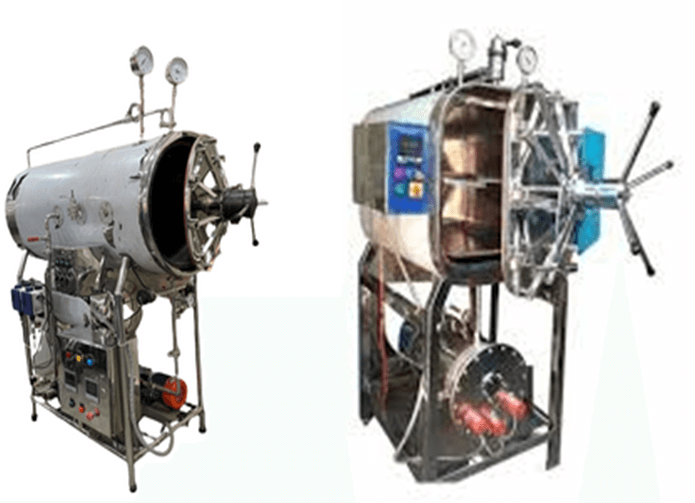

Horizontal Autoclave

- Specifications

- Key Features

Material:

- Stainless Steel 304 / 316 Grade & Other Alloys

Control & Safety Features:

- Manual operation or Touch Screen HMI control

- Two safety valves & pressure switch to prevent accidental pressure buildup

- Low water level device for heater protection

- Auto water filling unit

- Pressure lock device for door safety

- Operates at 121°C / 134°C with 20 / 32 PSI (1.5 to 2.2 kgf/cm²)

- Hydrostatic pressure tested at twice the working pressure

- Vacuum system for effective drying

Construction Details:

- Chamber Thickness: 4 mm (S.S. 316 / 304 grade)

- Door Thickness: 12 mm (S.S. 316 / 304 grade)

- Jacket Thickness: 6 mm (S.S. 316 / 304 grade)

- Steam Generator: 18 KW (Stand S.S. 304 grade / Powder coated)

- Steam Pressure Lock Hydraulic Device for door safety

- Available in Single Door & Double Door options

Power Supply:

- 9 / 12 / 18 KW, 440V, 3-phase

Temperature Controller:

- 121°C / 134°C

Cylindrical Sizes:

- 16×14 – Double Drum (305 mm x 380 mm)

- 20×36 – Three Drum (305 mm x 380 mm)

- 20×48 – Four Drum (305 mm x 380 mm)

- High-Quality Construction: Made from durable Stainless Steel 304 / 316 grade for long-lasting performance.

- Advanced Control System: Available in manual or Touch Screen HMI operation for user-friendly control.

- Enhanced Safety: Equipped with two safety valves and a pressure switch to prevent accidental pressure buildup.

- Automatic Water Management: Features auto water filling and low water level protection for heater safety.

- Secure Door Locking: Pressure lock device and steam pressure lock hydraulic system ensure safe door operation.

- Precise Temperature & Pressure: Operates at 121°C / 134°C with 20 / 32 PSI (1.5 to 2.2 kgf/cm²) for effective sterilization.

- Superior Performance: Vacuum drying system for better sterilization results.

- Robust Design:

- Chamber thickness: 4 mm (S.S. 316 / 304 grade)

- Door thickness: 12 mm (S.S. 316 / 304 grade)

- Jacket thickness: 6 mm (S.S. 316 / 304 grade)

- Powerful Steam Generator: 18 KW capacity, available in 9 / 12 / 18 KW, 440V, 3-phase

- Flexible Door Options: Available in single door & double door

- Multiple Size Variants:

- 16×14 – Double Drum (305 mm x 380 mm)

- 20×36 – Three Drum (305 mm x 380 mm)

- 20×48 – Four Drum (305 mm x 380 mm)